Efficiency of materials

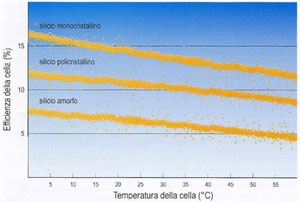

Only a part of radiogenic energy that beats on the cell is converted into electricity; the rate of conversion depends in a large part on the characteristics of the materials used and in general does not exceed 20%.

Obviously the energy yield from the equipment is a function of four factors: geographical and meteorological, orientation and inclination of the surface of the modules. As regards Italian latitudes maximum yield can be gained by orientating the module towards the south with an angle of 32-45° with respect to the horizon.

In standard conditions (25°C with 1kW/m²) a cell produces roughly 1.5 Watts (Wp peak power). Currently, the material most commonly used is crystalline (mono, poly or amorphous) silicone employed in a thin layer of between 0.25 and 0.35mm.

Polycrystalline, which is cheaper to produce, performs at 12-14%, and even lower if it contains a higher quantity of impurities.

Amorphous silicone, used in the so-called “thin film” technology, on the other hand, is sprayed in the form of gas on the panel surface. This technology is more convenient than the former method thanks to the fact that a lower quantity of material is required, thereby cutting the cost of production. Moreover it is highly versatile and flexible. The only, as yet unresolved, downside is its lower efficiency rate due to the unstable nature of amorphous silicone.

Also the systems with CIS and CIGS and cadmium telluride (CdTe) semi-conductors use thin film technology. CIS and CIGs have an efficiency rate of up to 13% and production costs slightly less than with silicone. However, the scarcity of materials like indium and selenium presents an obstacle to large-scale production.

In order to achieve higher performance studies are being conducted into multi-junction photovoltaic cells and cells with triple junction (split spectrum cells or vertical multi-junction cells). These are semi-conductors made of different materials, arranged one on top of another so as to have a larger spectrum of radiation absorption and hence higher performance, increasing the overall efficiency of solar energy conversion (reaching levels of over 30%).

Still in the production phase are organic cells, known as Dye Sensitised Solar Cells obtained through the use of nanotechnology. This type of product uses a photosensitive organic pigment able to absorb light and generate flows of electrons, applied in thin films made of a layer of nanoporous metal oxide and conductive polymers or liquid electrolytes. The distinguishing characteristic of DSSC technology is its high flexibility and suitability for use in a variety of forms and applications, besides being much less costly than traditional cells.

arkesrl@guidogroup.com PEC: info-arke@legalmail.it

C.F. - P.IVA: 03371190780

webdesign SkillGrafica

Registered office: Via L. Ariosto, 3 - 87100 - COSENZA (Italy) - tel. +39 0984 466654

North Italy operative branch: via Tonale, 9 - 20125 - MILANO - tel. +39 02 39289261

Central Italy operative branch: via Sante Bargellini, 4 - 00157 - ROMA - tel. +39 06 83952370

E.S.Co. Arké S.r.l.

PRIVACY POLICY