SOLAR HEATING

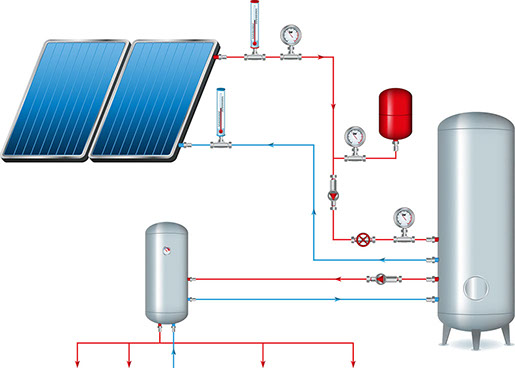

Plant components

Technical aspects

renewable energy

For a personalised consultation write to::

plant components

Solar Collectors

In general the following recommendations should be respected:

The thermal gap between the in-pipe and the exit pipe to the solar field must not exceed 15C° for traditional forced air systems in the maximum conditions of available insulation;

The maximum in the solar collectors for traditional forced air systems must not exceed 110 litres per hour for one square m of collector (erosion limit) and be below 50 litres per hour for one square m of collector;

For flat plate collectors, the number in a group (parallel collectors) must not exceed six, except in specific cases explained by the constructor.

For plant designed to work in line with the low-flow, matched-flow principle, or indirect exchange depletion different levels and gaps of temperature are allowed in line with the maker’s instructions.

The distribution system of the heat conductor must be balanced so as to have the same level for all the collector banks also by using, if necessary, the adjustment valve for each part of the plant.

The plant must be equipped with a safety valve and a means to top up antifreeze heat conductor fluid.

Every collector bank must have a tap and an air valve, manual or automatic, the latter placed at the highest part of the circuit.

Cisterns

Where required by the user, cisterns will be for hot water and drinking water, treated internally against rust, with maximum pressure of at least 6 bars.

As regards insulation, cisterns must conform to the DPR 412/93

Each cistern must be equipped with:

- Automatic air valve

- Replaceable expansion membrane

- Safety and heat release valve

- Temperature dial for hot water (only for custom built type)

- Pressure gauge and, wherever necessary, a pressure reducer.

In the case of a number of interconnected cisterns, a single pressure expansion tank, a single safety valve and a single hydrometer can be used.

For plants with more than one cistern, each cistern must be connected to the hydraulic network in such a way as to ensure it can be taken out of service to allow maintenance without impeding the functioning of the rest of the plant.

For forced air plants, vertical cisterns will be used. Horizontal cisterns can be used wherever, for logistical reasons, vertical ones are unsuitable.

In cases of:

- Direct link to the primary circuit with a utilisation characterised by thermal inertia, e.g. large scale tanks to be maintained at a given temperature, or by a high and continual flow from the secondary circuit (industrial applications);

- For heating swimming pools, the installation of plants without storage systems may be considered.

Exchangers

In systems above or equal to 50 m², the use of plate heat exchangers is required. The specific surface must not be less than 0.1m per m² of installed surface for this type of exchanger.

The maximum temperature of the exchanger in use must be at least 160°C and maximum pressure at least 6 bars.

Centrifugal Pumps

Centrifugal pumps must be able to function with a mix of water and antifreeze that guarantees protection in temperatures of at least 10°C below the designed temperature in the location of the installation (second table L10/91).

Moreover, these must be able to withstand temperatures of 120°C and the maximum pressure of the plant in use, and must be equipped with at least two functioning speeds.

Other components

For every closed circuit, an expansion tank must be installed, except for drain back systems. This must be constructed with the materials of the right composition and size, and installed on lines laid down in DM 1/12/76, as well as in accordance with the norm (ex ANCC-Raccolta R.). The expansion tanks must be marked CE, or an equivalent to ISPESL.

For forced air systems above 100 m² an acoustic and/or visual system is required to signal loss of heating fluid from the plant.

The location and installation of all heat gauges must ensure contact with the parts to be measured, and must be isolated from external temperature.

Piping

For the primary circuit the connecting piping must have the following characteristics:

- Heat resistance of between -20°C and 200°C;

- Pressure resistance;

- Resistance to the chemicals in heating fluid.

The following materials can be used:

- Black steel without joints or soldering, galvanised steels;

- Copper.

In the event of galvanised steel pipes coming into contact with copper elements, it is necessary to employ dielectric junctions to prevent direct contact.

The use of piping in synthetic materials is permitted, provided these are compatible with the high pressure and high temperatures that can occur while the plant is in use.

arkesrl@guidogroup.com PEC: info-arke@legalmail.it

C.F. - P.IVA: 03371190780

webdesign SkillGrafica

Registered office: Via L. Ariosto, 3 - 87100 - COSENZA (Italy) - tel. +39 0984 466654

North Italy operative branch: via Tonale, 9 - 20125 - MILANO - tel. +39 02 39289261

Central Italy operative branch: via Sante Bargellini, 4 - 00157 - ROMA - tel. +39 06 83952370

E.S.Co. Arké S.r.l.

PRIVACY POLICY